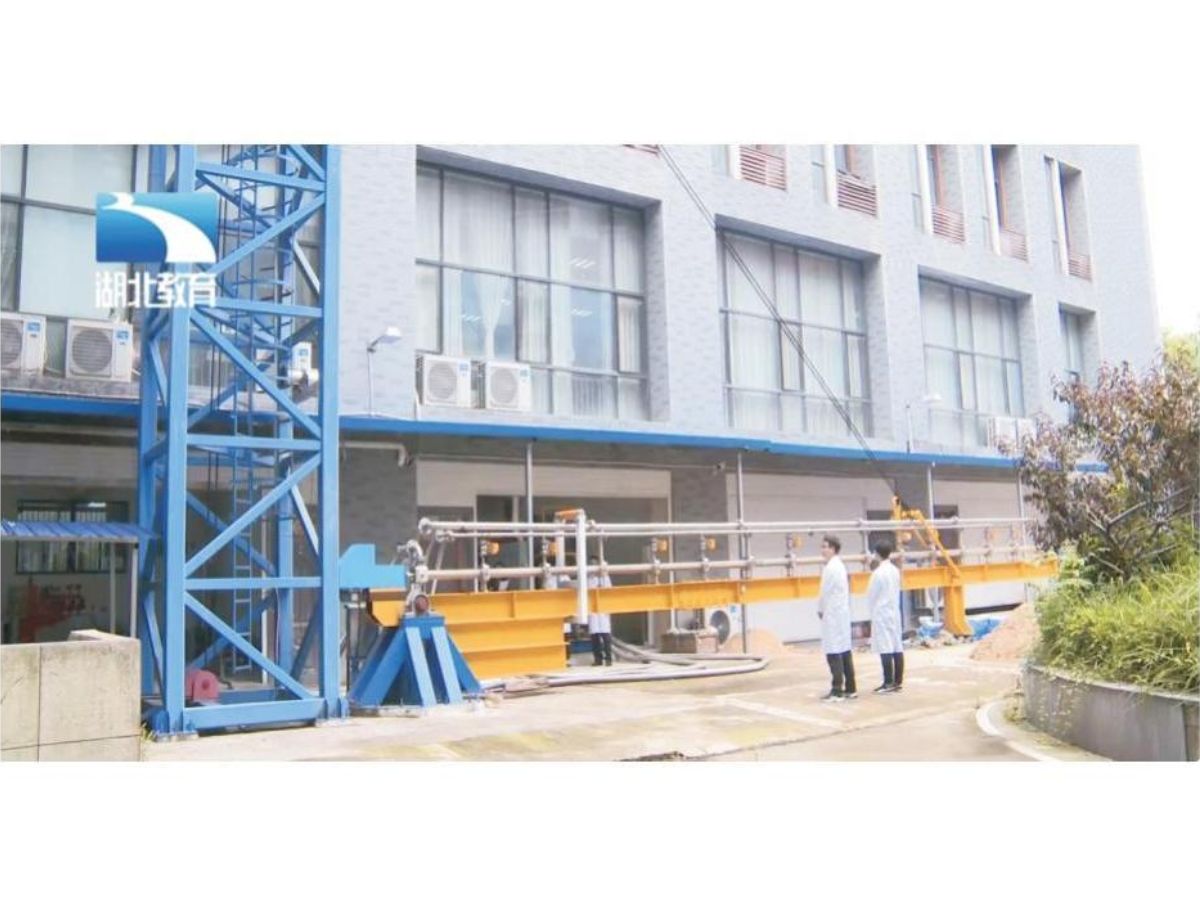

Intelligent drilling fluid-solid coupling simulation test device

Intelligent drilling fluid-solid coupling simulation test device

Intelligent drilling fluid-solid coupling simulation test device

The intelligent drilling fluid-solid coupling simulation testing instrument-expansion platform is mainly used to study the influence of the interaction between the wellbore annulus, drill string, and formation during drilling under complex conditions. It can observe and analyze the flow pattern under gas-liquid coexistence and test the performance parameters of drilling fluid.

Technical Parameters |

|

| Maximum Operating Temperature | 70℃ |

| Minimum Safe Pressure | 1MPa |

| Simulated Wellbore Length | 15000mm |

| Casing | The material is transparent plexiglass, with a pressure resistance of no less than 0.7 MPa |

| Torque Sensor Range | 0~100N ·m, 0~150r/min |

| Electric Cylinder Stroke Range | 10~20mm |

| Liquid Flow Rate Range | 0.5~2.5m/s |

| Gas Flow Rate Range | 3~10m/s |

| Industrial Camera | Frame rate ≥100FPS, can resolve 1mm particles within the field of view |

| Density Test Accuracy | 0.001g/cm³ |

| Pressure Test Accuracy | 0.1% |

| Flow Rate Test Accuracy | 0.5% |

Instrument Functions

Directional remote control of the leakage point and wellhead surge point in the simulated wellbore, high-precision remote adjustment of the loss and surge volume; simulation of the morphological changes of the drill string under the action of the extrusion and rotation device, with accurate measurement of drilling speed and axial force; visualized design of the casing combined with a high-speed industrial camera and shadowless light source to meet the real-time image acquisition of the flow pattern of the medium in pipes with different inclination angles; the simulated casing connection is an easily disassembled mechanical structure, allowing for customized replacement of any section of casing as needed; simulation of the release of the retaining pin in the cemented casing head, observing and analyzing the influence of this action on the flow pattern of the medium in the wellbore; capable of forming a multiphase flow experimental medium composed of solid, gas, and liquid, with accurately adjustable proportions of each phase substance; evaluation of the characteristics and effectiveness of any type of drilling fluid, providing theoretical support and experimental verification for optimizing drilling fluid formulations; the host computer remotely controls the flow rate and pressure of the fluid through PLC, and performs online monitoring and data acquisition of parameters such as density, flow rate, and pressure of the fluid medium. The collected data can be transmitted to a designated server, and an RTOC display system is built on this basis.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Contact Us

Email:clkjxs@cnclkj.com

Mobile:18672122616

Address: No. 8, Weiwu Road, Development Zone, Jingzhou City, Hubei Province

Follow Us

Powered by www.300.cn This website supports IPV6 access

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home